Efficient load planning is a critical factor in reducing transportation costs and maximizing the profitability of each truckload. In this article, we discuss key load planning strategies that optimize deliveries, reduce costs, and ensure transportation is efficient, safe, and compliant with regulations.

The Importance of Load Planning

Properly planning the load of a vehicle or container enables more efficient deliveries and better resource utilization. Load planning is the foundation of route optimization, helping drivers reach their destinations and ensuring your company meets legal requirements for transporting goods. As a result, cost savings, optimized deliveries, and satisfied customers are achieved.

With well-planned load planning, route planning can also be improved, as the best loading sequence allows for faster, easier, and safer loading and unloading.

In this article, we explain what load planning is and which key factors should be considered to optimize your deliveries efficiently. Additionally, we will discuss some practical steps to improve your load planning and reduce costs.

What is Load Planning and Why is it Important?

Load planning is a central part of logistics management, focusing on the efficient arrangement and placement of goods in vehicles (such as vans and trucks) and other transport units.

The main objective of load planning is to minimize delivery and transportation costs while maximizing the capacity of each load and ensuring a smooth delivery flow for drivers.

Properly executed load planning reduces delivery costs and vehicle wear and prevents unnecessary stops by ensuring each load is utilized optimally. Poor planning can result in damaged products, long delivery times, or penalties due to overloading and regulatory violations.

The goal of every load planner is to transport goods efficiently, safely, and smoothly from point A to point B.

Responsibilities of a Load Planner

Load planners are responsible for coordinating and documenting the entire process. They track records, ensure the correct documents are available for each load, and facilitate clear communication with warehouse teams and drivers.

They collect all details of a shipment, including:

- Product type

- Transportation requirements

- Potential route restrictions

Additionally, they make decisions that enhance workflow efficiency, profitability, and speed.

Load Optimization

Load optimization is a scientific method used to maximize the benefits of each full truckload. This is often done using specialized planning tools and optimization software. Load configuration and weight balancing are part of this planning process.

Load planning and load optimization are often used interchangeably since both aim to improve the delivery process and vehicle capacity.

Items should be loaded to remain secure during transport. Furthermore, the load planner must ensure that the vehicle’s weight is evenly distributed to meet total weight and axle load requirements for safer driving.

Another important aspect is how goods are stored in the vehicle. For example, if a van is loaded for multiple deliveries and the first stop’s packages are in the middle, they may need to be rearranged to access the correct item, leading to delivery delays. The load planner optimizes the loading process based on the sequence of stops.

Resource Efficiency

Partially loaded vehicles and low-tonnage shipments per truck significantly increase operational costs. By optimizing each load according to the target delivery route, load planners ensure easy unloading and maximize the load capacity of each vehicle.

This leads to fewer trips, reduced tire and brake wear, and less stress on drivers. The company benefits from lower fleet maintenance costs, reduced fuel expenses, and improved driver retention.

Fine-tuning load planning makes each delivery more cost-effective and strengthens operational resilience.

Key Factors in Reducing Delivery Costs with Load Planning

Load planners function like a busy transportation hub. They work in airports, distribution centers, and shipping facilities, ensuring the entire supply chain operates efficiently. Their work has a major impact on supply chain effectiveness.

An experienced load planner is not only responsible for logistics planning but also for ensuring timely and cost-effective deliveries. They coordinate drivers and packaging teams, ensure compliance with regulations, and optimize workflow.

Essential Elements of Load Planning

Several factors must be considered to optimize deliveries and reduce costs, including:

- Regulatory Compliance: Adhering to transportation regulations prevents fines and legal issues. Load planners ensure all regulations are met and shipments are properly documented.

- Load Safety and Balance: Proper placement of packages helps maintain vehicle stability when braking or turning. Poor loading can cause goods to shift, leading to accidents.

- Better Space Utilization: Efficient load placement reduces the number of trips, lowers transportation costs, and minimizes safety risks.

- Time, Cost, and Operational Efficiency: Fewer trips mean reduced labor, lower fuel costs, and decreased maintenance expenses. Optimized load configurations and sequences minimize waiting times.

- Environmental Impact: Unplanned trips and inefficient loading increase CO₂ emissions. Efficient loading helps reduce environmental impact and emissions.

The Synergy Between Route and Load Planning

Combining load planning and route optimization creates dynamic and efficient processes. By optimizing the route before loading, the load can be properly planned and arranged. This maximizes vehicle utilization, minimizes empty space, and reduces transportation costs.

With the right software solution, routes can be optimized within minutes and integrated with the load planning system. This prevents unnecessary detours and allows for quick implementation of last-minute changes.

The Use of Load Planning Software

Load planners use software solutions to track shipments and deliveries. Manual planning is prone to errors and can be inefficient, especially in large operations. Transportation management software and warehouse management systems help quickly configure loads and maximize vehicle capacity.

When integrated with route planning software, planning becomes even more optimized. Drivers can track and easily locate packages during delivery, making the process more efficient.

Practical Tips to Improve Load Planning

- Invest in Technology: Choose software solutions that align with your company’s needs and increase efficiency.

- Training and Clear Communication: Ensure load planning teams receive proper training to implement processes effectively.

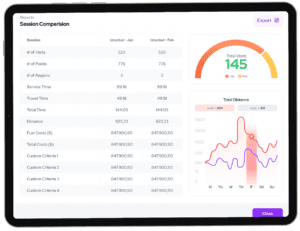

- Continuous Improvement: Regularly analyze data and use reporting tools to continuously enhance your processes.

Load planning is a fundamental component of the transportation industry, enhancing efficiency in the delivery process. It provides cost savings for both small and large businesses, increases safety, and reduces environmental impact. Ultimately, load planning and route optimization are key to improving logistics processes, reducing costs, and staying competitive.